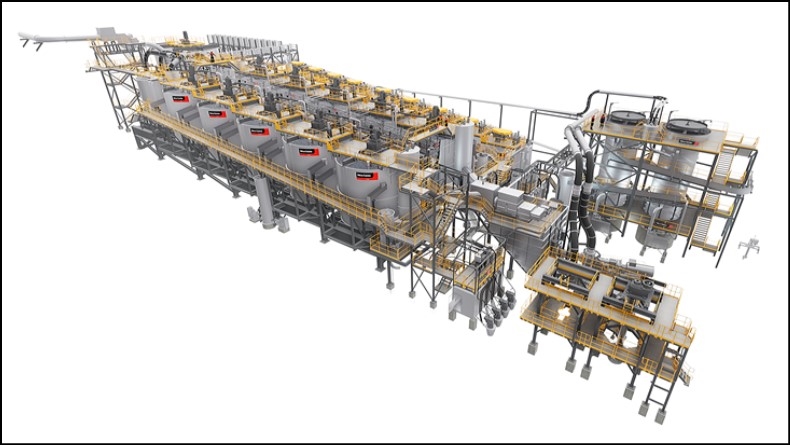

Metso Outotec introduces complete flotation plant unit to maximize performance

Metso Outotec is introducing yet another innovative plant concept, flotation plant units, to its minerals processing portfolio. The solution provides unparalleled metallurgical performance by seamlessly integrating functional design with a comprehensive scope. The result is high operational reliability and a fast return on investment. Compared to the traditional delivery, flotation plant units result in the earliest time-to-volume.

In flotation, changing ore types can cause recovery losses, and poorly integrated plant equipment leads to underperformance. Maximizing overall performance and reliability requires in-depth understanding of the complex flotation circuit sizing. All these concerns have been taken into consideration in the design of the Metso Outotec modularized flotation plant units to provide unmatched results.