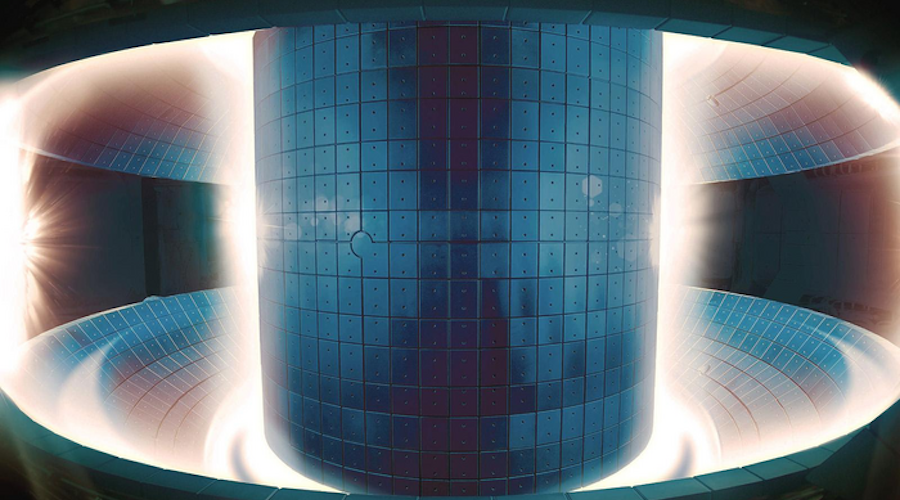

Jacob Haag, first author of the paper, explained that the sun—with a core temperature of around 27 million degrees Fahrenheit—is powered by nuclear fusion. Thus, it should come as no surprise that fusion reactions produce a lot of heat. This means that before scientists can harness fusion energy as a power source, they need to create advanced nuclear fusion reactors that can withstand high temperatures and irradiation conditions that come with fusion reactions.

Tungsten is one of the elements with the highest melting points, which makes it a particularly attractive material for use in fusion reactors. However, tungsten can also be very brittle. Mixing it with small amounts of other metals, such as nickel and iron, creates an alloy that is tougher than tungsten alone while retaining its high melting temperature.

According to Haag, it isn’t just their composition that gives these tungsten-heavy alloys their properties—thermomechanical treatment of the material can alter properties like tensile strength and fracture toughness.

Like seashells

A particular hot-rolling technique produced microstructures in tungsten-heavy alloys that mimic the structure of nacre, also known as mother-of-pearl, in seashells. Nacre is known to exhibit extraordinary strength. The PNNL and Virginia Tech research teams investigated these nacre-mimicking tungsten-heavy alloys for potential nuclear fusion applications.

To get a closer look at the microstructure of the alloys, Haag and his group used scanning transmission electron microscopy to observe atomic structure. They also mapped the nanoscale composition of the material interface using a combination of energy-dispersive x-ray spectroscopy and atom probe tomography.

Within the nacre-like structure, the tungsten heavy alloy consists of two distinct phases: a ‘hard’ phase of almost pure tungsten, and a ‘ductile’ phase containing a mixture of nickel, iron, and tungsten. The research findings suggest that the high strength of tungsten-heavy alloys comes from an excellent bond between the dissimilar phases, including intimately bonded ‘hard’ and ‘ductile’ phases.

“While the two distinct phases create a tough composite, they pose significant challenges in preparing high-quality specimens for characterization,” Wahyu Setyawan, PNNL computational scientist and co-author of the paper. “Our team members did an excellent job in doing so, which enable us to reveal the detailed structure of interphase boundaries as well as the chemistry gradation across these boundaries.”

The study demonstrates how crystal structure, geometry, and chemistry contribute to strong material interfaces in tungsten-heavy alloys. It also reveals mechanisms to improve material design and properties for fusion applications.

“If these bi-phase alloys are to be used in the interior of a nuclear reactor, it is necessary to optimize them for safety and longevity,” Haag said.