This successful program concluded with the customer purchasing a license to use the RPM solution.

The main benefits of using SDO include its ease of use, ability to evaluate strategic scenarios quickly and the ability to analyze more scenarios with robust analysis in decision making.

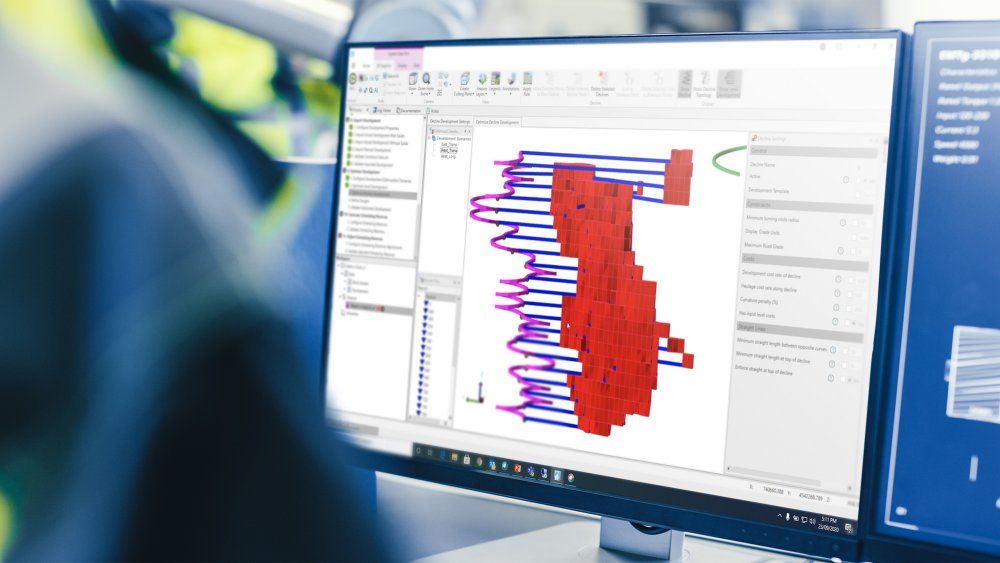

SDO includes the industry-standard Mine Shape Optimizer (MSO), which rapidly generates the first pass development using RPM’s Development Optimizer, eliminating the requirement for the user to draw every part of the mine design. This allows end-users to perform their strategic design work in one package.

With SDO, users can make small tweaks to designs in one area and have those changes ripple through the rest of the design, a task that would otherwise take days in traditional CAD-based packages as each edit would need to be done manually.

Commenting on this sale, Richard Mathews, RPM CEO, said it was a reflection of the product team’s dedication to successfully bringing SDO to market through strong partnerships and industry collaboration.

“It’s very pleasing to see SDO gaining traction in the North American market, and we are confident this sale will spur further interest in our leading strategic design packages heading into 2021.”

SDO is unique in that it uses parametric design principles, combined with several leading optimization algorithms, in a single user experience. SDO integrates both the stope and development optimization into a single package, allowing customers to generate, change and update designs on the fly.

The design tool emphasises the visualization of results on plots, graphs and tables, allowing the user to quickly interpret and select with confidence the best scenarios to bring forward for more detailed designs.

Strategic options can then be quickly filtered by scenarios that maximize value and eliminate unviable scenarios early.

“RPM remains committed to providing its customers with the most advanced mining technology solutions and our continued investment in the design and scheduling suite will help ensure mine planners continue to unlock new levels of capability,” Mathews concluded. “It is fair to say we are passionate about assisting the industry solve complex problems at every stage of the mining value chain, and we are looking forward to helping many more operations deliver a fundamental step-change in the mine planning and design phase with the application of our integrated design applications.”

For more information, visit www.RPMGlobal.com.