Metso, Malvern to collaborate bulk ore sorting solutions to cut waste, costs

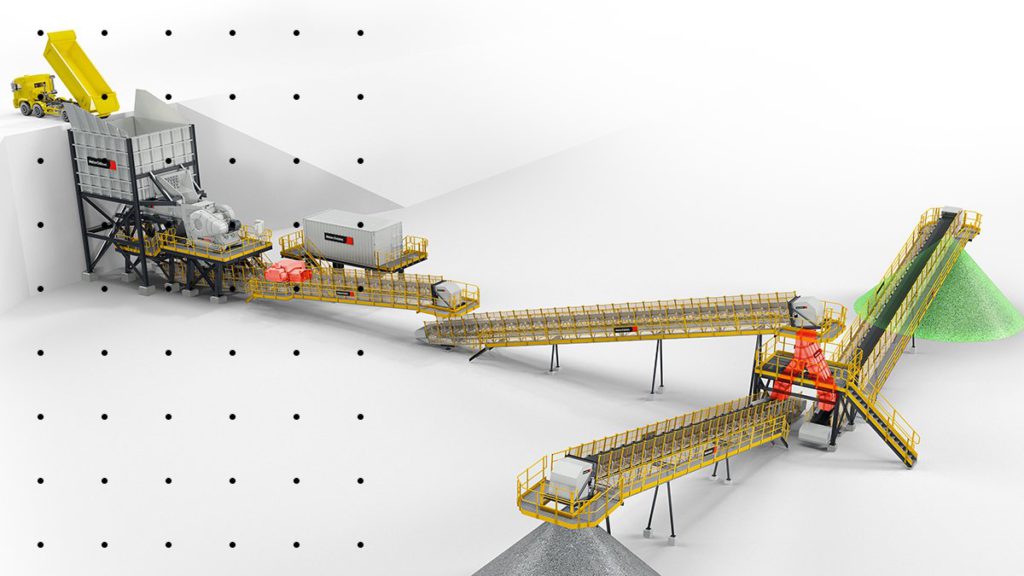

Metso Outotec and Malvern Panalytical have signed a collaboration agreement to provide sensor-based bulk ore sorting solutions for the mining industry. The combination of the companies’ expertise in crushing and bulk material handling solutions and ore analyzers is intended to result in an industry-leading portfolio of solutions for bulk ore sorting.

With this offering, mining customers can substantially improve head grade by preconcentrating the ore at the crushing stage and thereby reduce their energy consumption and related environmental footprint in the grinding stage.