Courier 8X SL will replace Courier 8 SL in Metso Outotec’s automation portfolio, and the previous generation 8 SL can be easily by replacing some main components.

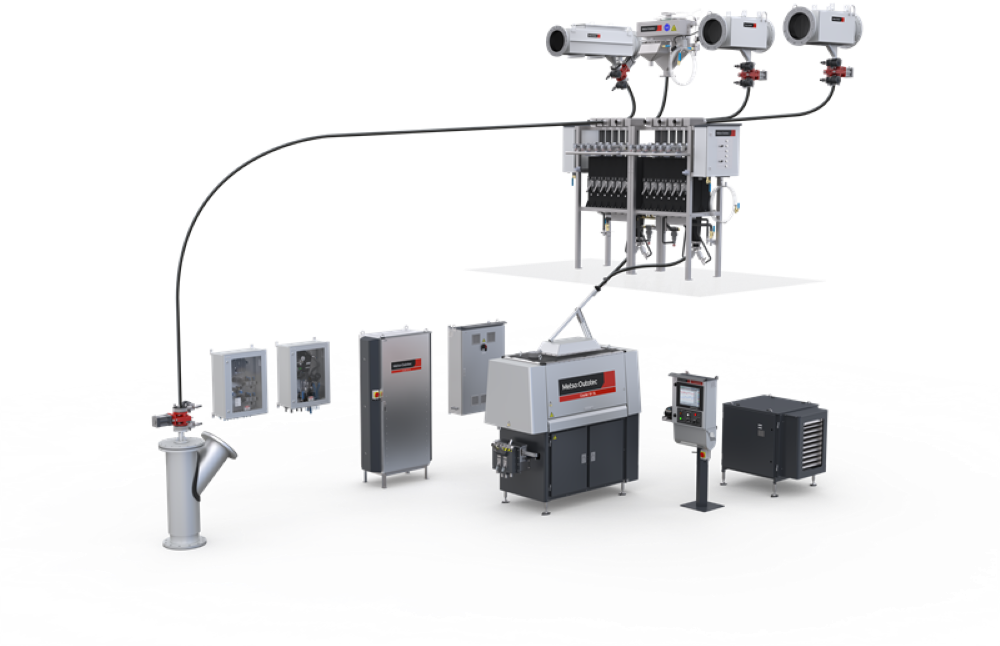

Compared to the earlier model, the Courier 8X SL offers improved temperature control, robustness and serviceability. Measurement speed is doubled, and the cycle time is 30% shorter. Higher precision is possible due to more stable slurry flow and the diode pumped laser. The 8X SL comes with next-generation Courier X software. Finally, connectivity features enable remote support and calibration services, together with Metso Outotec Metrics with KPI reporting to ensure improved equipment availability.

Metso Outotec also offers lifecycle services (LCS) for the Courier 8X to ensure the highest possible availability and measurement accuracy for the analyzer equipment. LCS combines available spare parts, maintenance and calibration expertise with market-leading digital monitoring and support tools, such as Metso Outotec Metrics supported by Performance Center services.

Metso Outotec Courier analyzers have been on the market for more than 50 years. Today, the portfolio consists of Courier 5X, Courier 6X, and Courier 6G SL for precious metals and Courier HX analyzers for hydrometallurgical processes.

Find out more about Courier 8X SL on the Metso Outotec website.