Commissioning of phase one of First Cobalt’s low-carbon hydrometallurgical refinery is scheduled for the fourth quarter of 2022, targeting annual production of 25,000 tonnes of cobalt sulphate annually

Once operational, First Cobalt’s refinery will be the only producer of battery-grade cobalt for the North American electric vehicle (EV) market, capable of supplying over 1 million vehicles per year, responding to strong and growing demand.

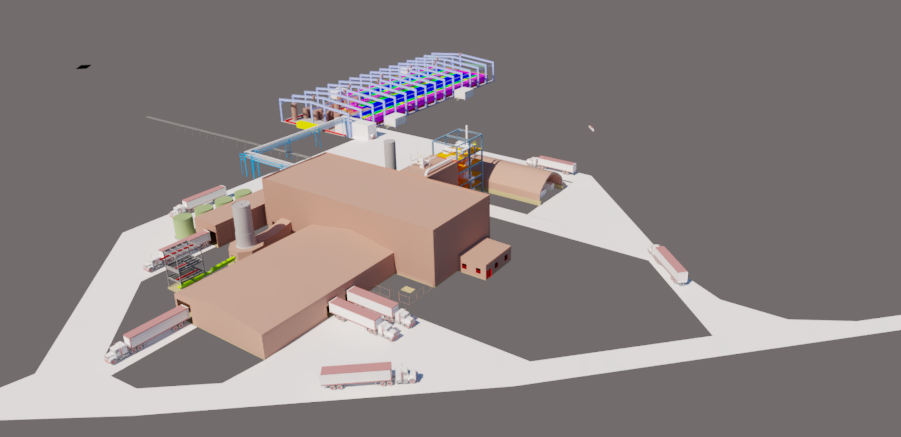

Metso Outotec’s solution involves the latest advancements in solvent extraction in terms of modular design, process control and ease of installation and startup. The installation time of the modular mixer-settlers will be 30% less than conventional equipment used at other projects. In addition to the reduction in site install time, the footprint needed for the selected plant equipment is less than conventional solvent extraction equipment.

Phase one deployment of First Cobalt’s three-phase approach to market entry will focus on processing cobalt hydroxide to produce a high-quality, sustainable and traceable battery-grade cobalt sulphate.

For more about the solvent extraction technology, visit Metso Outotec’s website.