According to the scientists, even though silver nanoparticle inks are currently the most commonly used in printed electronics, these inks are expensive and poorly compatible with soldering. Copper nanoparticle inks, on the other hand, are considered a viable, cheaper alternative but the issue with them is that they are extremely susceptible to oxidation, making them unsuitable for use in printed electronics.

Knowing this, the NIMS materials experts decided to conduct research on inks composed of complexes of organic amine ligands with a central metallic ion; these inks are stable in the air.

The team subsequently discovered that inks containing a mixture of different metallic complexes are capable of converting into different types of printed metallic patterns, including multilayered core-shell nanostructures and alloys, depending on the ink’s composition and other conditions.

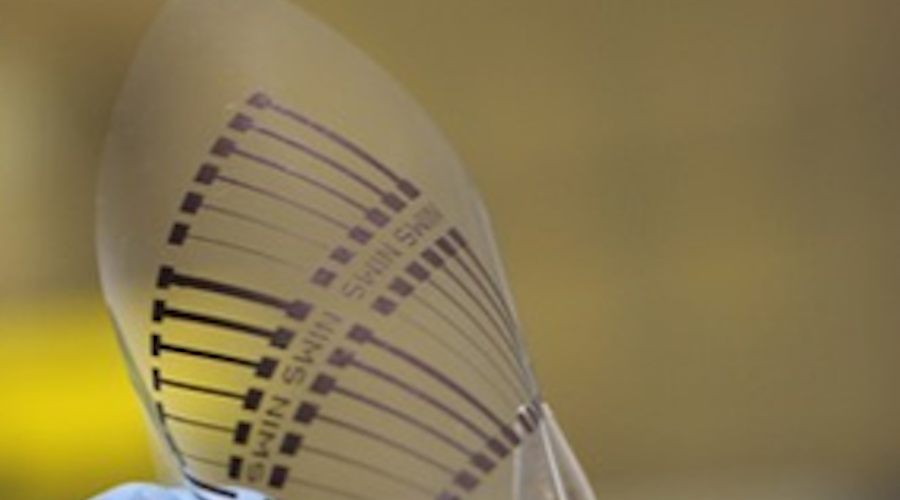

Based on these findings, they created the new ink, which is composed of a mixture of copper and nickel complexes able to self-organize into a copper core–nickel shell nanostructure. Because its outer nickel layer is resistant to oxidation, this printed pattern is significantly more resistant to oxidation than patterns printed using conventional copper inks.

The new ink is also cheaper than the currently available silver nanoparticle inks. Moreover, the electrical resistivity of conductive patterns printed using this ink was no more than 19 μΩ·cm, indicating that the conductivity of these patterns is comparable to patterns printed using conventional metallic inks.

The scientists believe that the addition of fine copper powder to this ink will increase its ability to form thicker layers. Thus, they are currently designing this new ink formulation in collaboration with the developers of the copper powder: Sumitomo Metal Mining and Priways, which plan to release sample ink products in the near future.